Lab facilities

Concrete Cylinder Compression Test

The Concrete cylinder compression test measures the strength of hardened concrete, assessing its capacity to withstand loads before failure. As the name suggests, it involves compressive strength testing by crushing concrete in a compression testing machine.

Many tests are conducted on concrete to ensure its quality and suitability for various construction applications.

However, engineers in structural design frequently use the compressive strength test as a popular performance measure because it provides contractors with information on the strength of concrete and how these potentially increase over time.

In most cases, concrete typically reaches full strength at 28 days, with 75% of this strength achieved in 7 days. Over time, concrete’s strength can increase due to hydration. Hydration is a chemical reaction where the primary compound in cement forms chemical bonds with water molecules. Water absorbs into the concrete, increasing its strength for years.

Water Penetration Test Concrete

Splitting Tensile Strength Test (Brazilian)

The Brazilian Test is a laboratory test conducted in concrete mechanics to indirectly determine the tensile strength of rocks.

The tensile strength of rock materials is an important parameter in designing a geotechnical project since it is significantly lower than the concrete ’ compressive strength. This phenomenon is also presented in concrete, a fact that led to the utilization of steel reinforcement to increase the tensile capacity of the material.

Research has also shown that during compression, the tensile strength in the tips of microcracks is exceeded and those cracks tend to propagate through the specimen leading to failure.

The tensile strength of a rock is mainly derived by two testing procedures:

- The Direct Tensile Strength test

- The Brazilian Test

The Direct Tensile Strength test is considered as the most proper method to derive the tensile capacity of a specimen. However, it is not widely utilized since sample preparation is challenging and the failure is usually invalid (the specimen should fail through its middle part so that the test is reliable).

For this reason, the Brazilian Test is widely used as the sample preparation and the testing procedure are far more efficient.

Lateral Jack For Frames

Lateral Jack is available in the laboratory for testing any structural members with the ability to set a cyclic load for it.

A data longer gives the displacements outputs and also a reaction forces

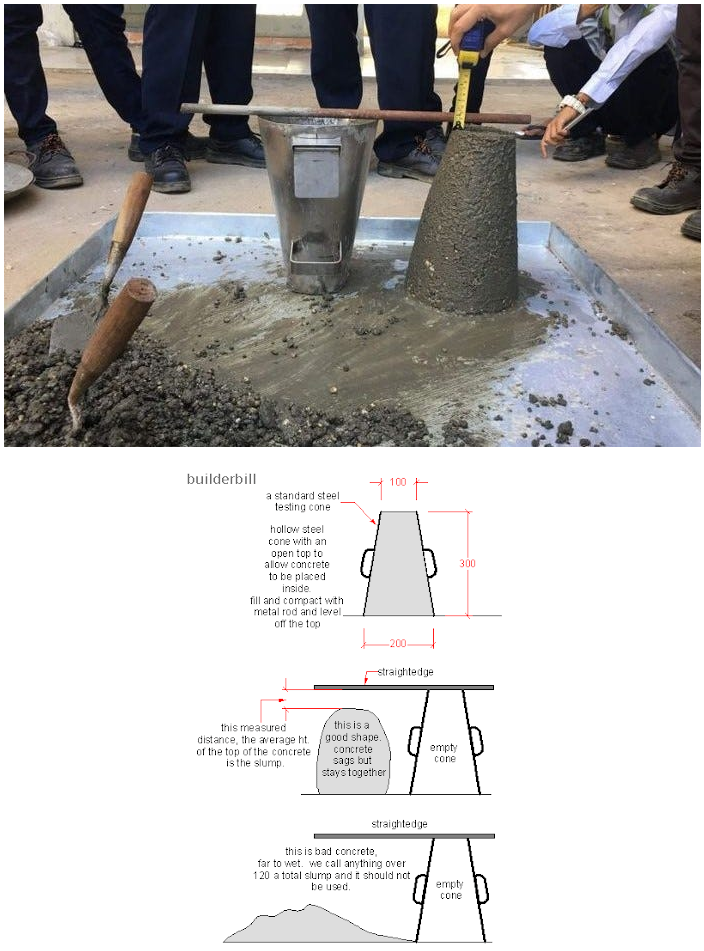

Cncrete Slump Test

What is the concrete slump test?

Freshly mixed concrete — that is soon to be poured — should meet a certain standard before being used as part of a construction project. A concrete slump test measures the consistency of a concrete batch to see how easily the concrete will flow. The test not only observes consistency between batches, but it also identifies defects in a mix, giving the operator a chance to amend the mix before it is poured on site.

By measuring the overall ‘slump’ of the concrete, you can tell whether or not the water-cement ratio is too high, and whether a mix will have high workability or not.

Why use a concrete slump test?

The main reason to perform the test is to ensure batches of the same concrete are of constant quality and strength. The more water is added to a mix, the weaker the concrete gets. If customers require a higher workability/more flowing concrete ( a higher slump result) we need to increase the cement content to ensure the concrete still reaches its target strength. This test is just one of the ways we ensure the quality of our concrete. Water is the enemy when it comes to concrete strengths.