Publications and Conference:

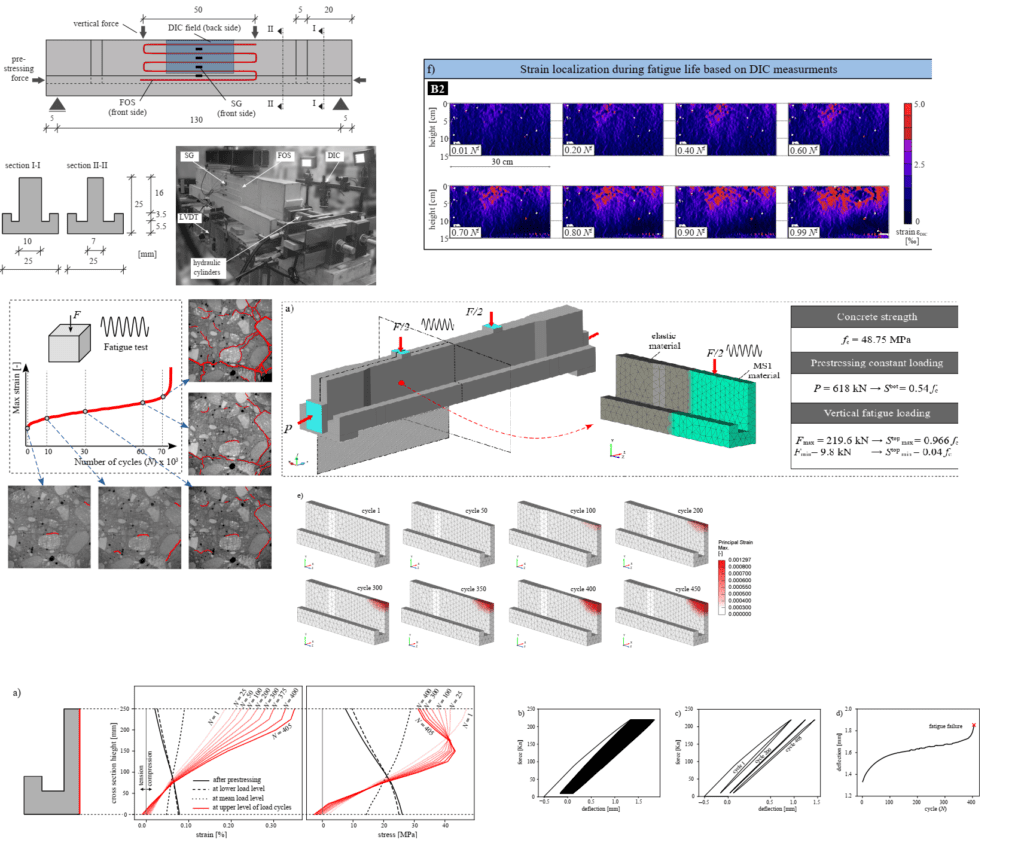

Fatigue-induced stress redistribution in prestressed concrete beams modeled using the constitutive hypothesis of inter-aggregate degradation

Fatigue & Fracture of Engineering Materials & Structures

Abedulgader Baktheer, Soheil Esfandiari; Mario Aguilar; Henrik Becks; Martin Classen; Rostislav Chudoba (2024)

Despite of intensive research on concrete fatigue, the transfer of fatigue characteristics determined at the material level to the structural level remains a challenging issue. In this paper, the propagation of fatigue-induced damage through the concrete structure is analyzed using a microplane fatigue model for concrete recently developed by the authors. To this end, our recent experimental study in which the fatigue propagation was monitored at the structural level represented by prestressed concrete beams is used to derive a general interpretation of the stress redistribution process using of the developed model. The numerical studies show that the developed microplane fatigue model provides a powerful computational tool for in-depth analysis of the correspondence between the fatigue behavior at the material and structural scales in a wide range of load configurations. In addition, the thermodynamically based constitutive model allows for the quantification of the energy dissipation during the process, revealing the possibility of deriving material-specific energetic characteristics that can further help to make the predictions of fatigue life more accurate

Full Paper available at:

https://onlinelibrary.wiley.com/doi/10.1111/ffe.14388

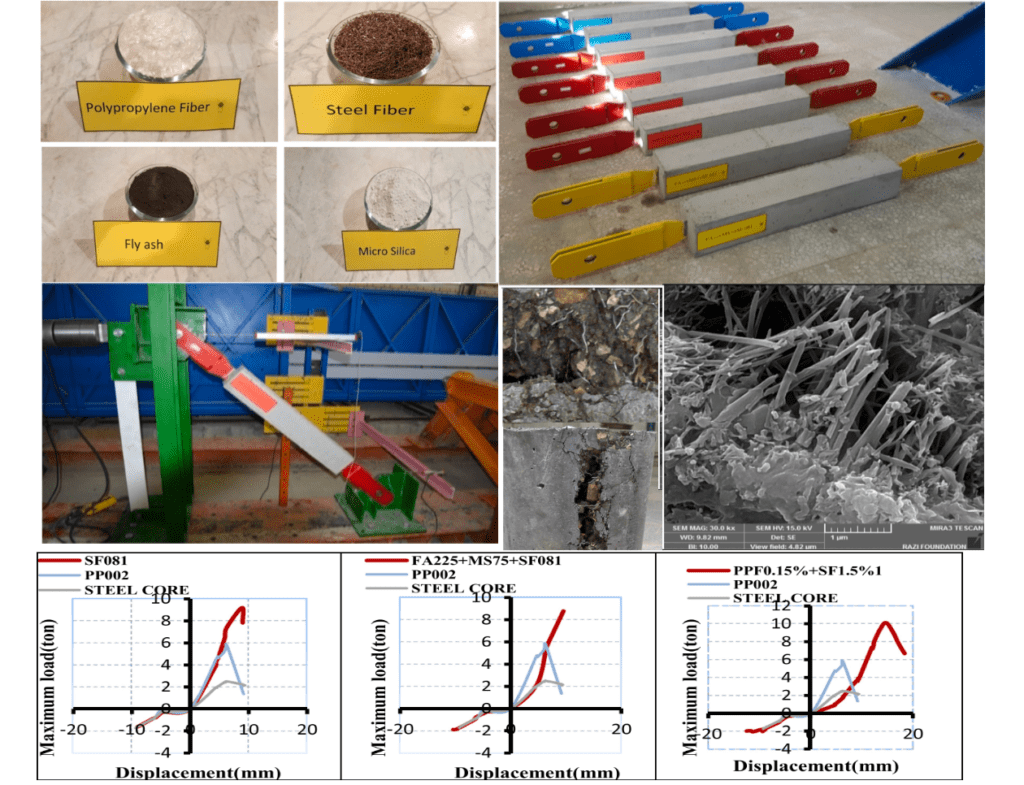

Modifying behavior of Buckling Restrained Braces by adding different admixtures to its concrete and using a cross-shaped core under Cyclic Loads

Case Studies in Construction Materials

J. Esfandiari, Heidari, S. Esfandiari, (2023)

This study explores the advantages of using steel fibers in concrete, particularly sinusoidal and hooked fibers, in earthquake-prone regions. Steel fibers enhance mechanical properties, improve concrete matrix, increase ductility, control crack width, and minimize crack propagation. The research involves creating samples of non-fibrous concrete and concrete with varying percentages of steel fibers and polypropylene. After identifying the optimal percentage for both compressive and tensile strength, seismic parameters, hysteresis curves, energy absorption, lateral displacement, and the impact of these fibers are investigated under specific loading conditions. Additionally, the study examines the environmental benefits of incorporating fly ash and micro-silica into concrete, which can replace some of the cement. The research also assesses the role of fly ash and micro-silica in preventing the buckling of buckling restrained braces.

Full Paper available at:

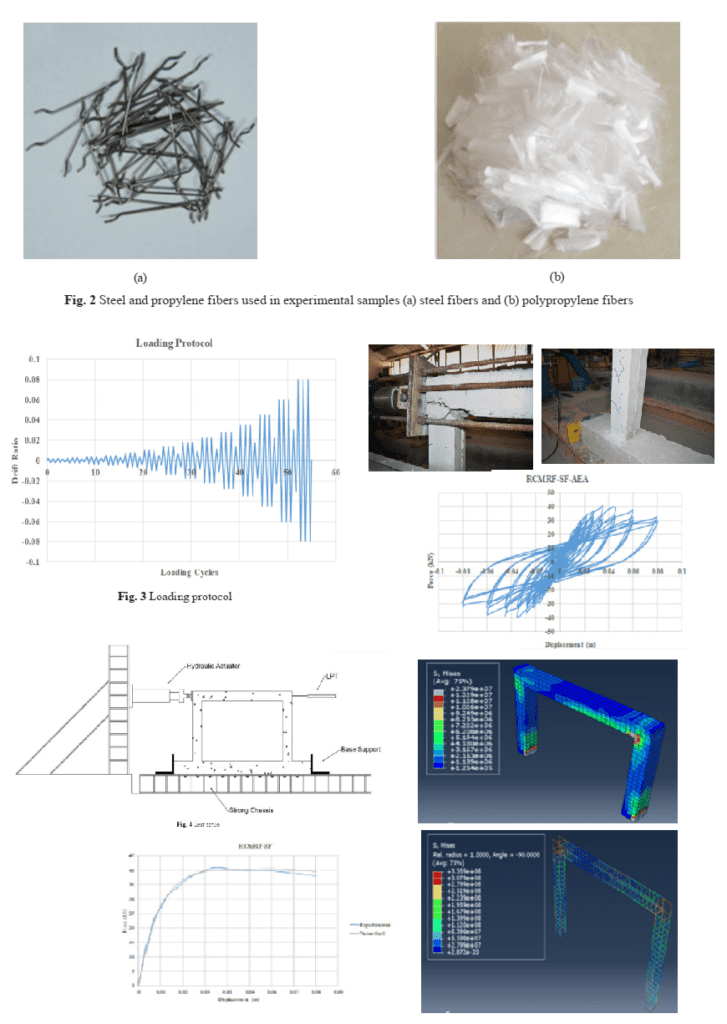

Experimental and Numerical Investigation of the Seismic Performance of RC Moment Resisting Frames

Periodica Polytechnica Civil Engineering peer reviewed scientific journal

Javad Esfandiari, Mehrzad Tahmouli Roudsari, Soheil Esfandiari (2024)

The rehabilitation of concrete structures has been a subject of extensive investigation, exploring various facets. One such avenue involves the incorporation of fiber additives into concrete materials. In parallel, the construction of reinforced concrete structures inevitably encounters construction errors, necessitating constant efforts from researchers to devise solutions for mitigating their impact. In the context of this research, a series of experiments was conducted involving the construction and testing of five reinforced concrete moment-resisting frames. The initial sample served as the control, while two additional samples were integrated with polypropylene and metal fibers. The subsequent two samples deliberately introduced a manufacturing error through the application of air-entraining admixture materials at the beam-to-column connection. This deliberate error aimed to assess the influence of additive fibers on frames affected by manufacturing errors. Several critical parameters were subjected to evaluation, including ultimate strength, stiffness, ductility, energy dissipation capacity, and strength reduction factor. The results of these assessments demonstrated that the utilization of additive fibers contributes to an enhanced overall performance of the frames, as inferred from the aforementioned seismic parameters. Furthermore, it was established that the incorporation of these additive fibers substantially alleviates the impact of manufacturing errors on moment-resisting reinforced concrete frames. Although a significant reduction in energy dissipation capacity was observed in samples with manufacturing errors, the other seismic parameters remained relatively unaffected. Subsequently, numerical models were generated in ABAQUS software to validate the experimental findings, and their outcomes were compared with the results derived from the physical experiments.

Full Paper available at:

https://pp.bme.hu/ci/article/view/23367

Experimental and numerical investigation on RC moment-Resisting frames retrofitted with NSD yielding dampers

Advances in Concrete Construction

Esfandiari J, Esfandiari. S, Zanganeh E, (2022)

Retrofitting in reinforced concrete structures has been one of the most important research topics in recent years.

There are several methods for retrofitting RC moment-resisting frames. the most important of which is the use of steel bracing systems with yielding dampers. With a proper design of yielding dampers, the stiffness of RC frame systems can be increased to the required extent so that the ductility of the structure is not significantly reduced. In the present study, two experimental

samples of a one-third scale RC moment-resisting frame were loaded in the laboratory. In these experiments, the retrofitting effect of RC frames was investigated using Non-uniform Slit Dampers (NSDs). Based on the experimental results of the samples, seismic parameters, i.e., stiffness, ductility, ultimate strength, strength reduction coefficient, and energy dissipation capacity, were compared. The results demonstrated that the retrofitted frame had very significant growth in terms of stiffness, ultimate strength, and energy dissipation capacity. Although the strength reduction factor and ductility decreased in the retrofitted sample. In general, the behavior of the frame with NSDs was evaluated better than the bare frame.

Full Paper available at:

http://www.techno-press.org/content/?page=article&journal=acc&volume=13&num=4&ordernum=6

Modifying behavior of Buckling Restrained Braces by adding different admixtures to its concrete and using a cross-shaped core under Cyclic Loads

Sigma Journal of Engineering and Natural Sciences, Yildiz Technical University– Turkey

Ebn Abbas M, Bayat. R, Esfandiari S(2024)

Carbon fiber reinforced concrete (CFRC) is a composite material composed of hydraulic cement mortar and fine aggregate, enhanced with carbon fibers. Incorporating carbon fibers into the concrete offers several advantages, such as improved tensile strength, enhanced flexural strength, increased energy absorption capacity, better nonlinear behavior, and greater deformability. Researchers have consistently focused on understanding the long-term performance of carbon fibers in CFRC, as these properties are directly influenced by the conditions to which the carbon fibers are exposed on the concrete surface. One critical consideration is the concrete’s alkaline environment and the materials generated during cement hydration. Over time, carbon fibers can deteriorate, leading to changes in the mechanical properties of the CFRC. To mitigate the effects of the alkaline concrete environment, carbon fibers resistant to alkali are employed, and to counter the detrimental impact of the cement hydration process, various percentages of pozzolan are used. The study’s results highlight the substantial impact of mortar quality on the compressive strength of CFRC. Notably, the addition of carbon fibers tends to reduce the concrete’s compressive strength. However, the introduction of pozzolan in the mix minimizes the reduction in compressive strength and, in some cases, even leads to an increase in compressive strength compared to non-reinforced specimens. Additionally, the study reveals that the use of carbon fiber significantly enhances the modulus of rupture. Initially, the rupture modulus increases with an increasing amount of carbon fiber, but it eventually decreases over time. In summary, incorporating carbon fiber in concrete results in increased compressive and flexural strengths.

Full Paper available at:

Strengthening of reinforced concrete columns in compression axial rapid loading with FRP sheets

Advances in Concrete Construction

• Esfandiari. S, Esfandiari J, (2016)

In most cases strengthening reinforced concrete columns exposed to high strain rate is to be expected especially within weak-designed structures. A special type of loading is instantaneous loading. Rapid loading can be observed in structural columns exposed to axial loads (e.g., caused by the weight of the upper floors during a vertical earthquake and loads caused by damage and collapse of upper floors and pillars of bridges). Subsequently, this study examines the behavior of reinforced concrete columns under rapid loading so as to understand patterns of failure mechanism, failure capacity and strain rate using finite element code. And examines the behavior of reinforced concrete columns at different support conditions and various loading rate, where the concrete columns were reinforced using various counts of FRP (Fiber Reinforcement Polymer) layers with different lengths. The results were compared against other experimental outcomes and the CEB-FIP formula code for considering the dynamic strength increasing factor for concrete materials. This study reveals that the finite element behavior and failure mode, where the results show that the bearing capacity increased with increasing the loading rate. CFRP layers increased the bearing capacity by 20% and also increased the strain capacity by 50% through confining the concrete.

Full Paper available at:

Examining of openings in bearing capacity and ductility of semi-tied shearing steel walls and strengthening with steel

2nd International Conference on Civil Engineering, Architectural, Urban planning, Manchester, England

Esfandiari. S, Nasrollahi S, (2021)

Steel shear wall (SPSW) was introduced as a system resistant to lateral loads and was used in some buildings. In recent decades, the structural features of this system such as hardness,

The totality and absorption of energy have been widely investigated analytically, experimentally, and numerically. In order to eliminate the stresses caused by the tensile field on the columns of the structure that are connected to the wall sheet, it was assumed that the wall sheet is only connected to the beams of the floors. This idea led to the proposal of semi-confined steel shear walls in the previous decade. In semi-bonded steel shear walls, the wall sheet is not connected to the main columns of the frame and instead is connected to the sub-columns that are used only to create the tension field in the sheet. This research, in order to investigate the effect of using the opening and strengthening the semi-bound shear wall with a hardener, after examining the concepts and theoretical foundations. Analysis of the research sample, first a laboratory sample was modeled and verified and the results obtained from the laboratory model were compared and verified with the finite element model. The results indicate that creating a square opening has caused a 22% increase in ductility such as buckling of the shear wall. On the other hand, strengthening the shear wall has caused a 5% reduction in ductility such as buckling. It is noteworthy that in the models with rectangular openings and doors, deformation such as buckling has increased with wall reinforcement. The creation of a square opening has caused a 66% decrease in the maximum capacity of the shear wall. On the other hand, strengthening the shear wall has increased the maximum capacity by about 30%. In other models, the maximum capacity has been increased by retrofitting.

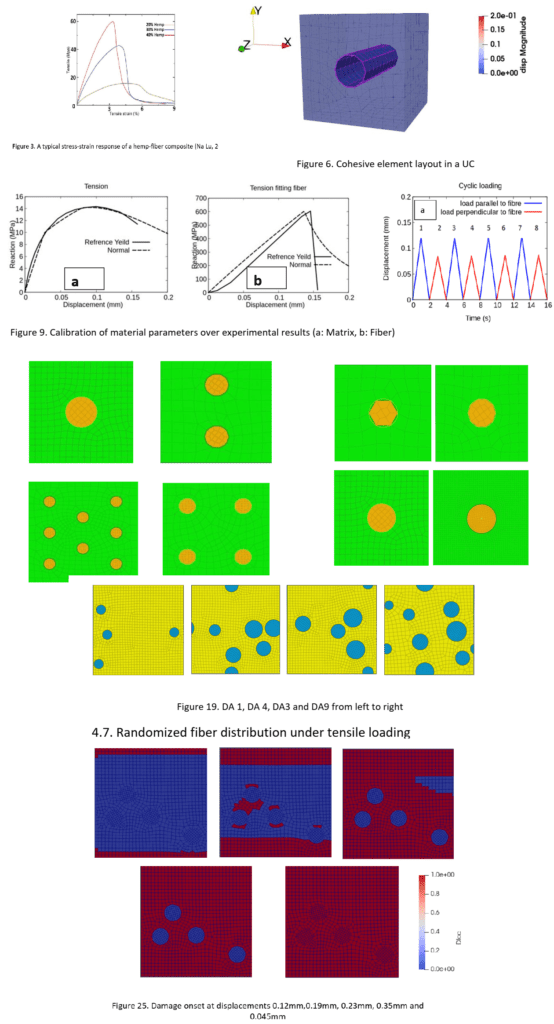

Meso-scale damage simulation of fiber-reinforced composite materials

RWTH University , Mini-Thesis Project

Soheil Esfandiari, Shiraj Baral , Ammu Menon, (2022)

Failure in composites, owing to their inherent anisotropy and heterogeneity, is complex and

not well defined. Damage accumulation occurs due to several failure mechanisms, namely

fiber fracture, fiber pull out, matrix cracking, or fiber debonding, their predominance however

strongly affected by material variables and testing conditions. In this study, the damage behavior of characteristic 3D unit cells of fiber-matrix composites subjected to tensile and shear loads are investigated using a gradient-extended two-surface damage-plasticity model. The effects of randomization of position, area, and the number of fibers are investigated to study the influence of geometry on the composite unit cell’s response. A Cohesive Zone Model is employed to compare the influences of strong and weak fiber-matrix interfaces in composites. Furthermore, the application of cyclic loading in tension is utilized to study the

effects of fatigue and corresponding stiffness degradation. The major influences of fiber area

and their distribution within the matrix on a composite has been studied.

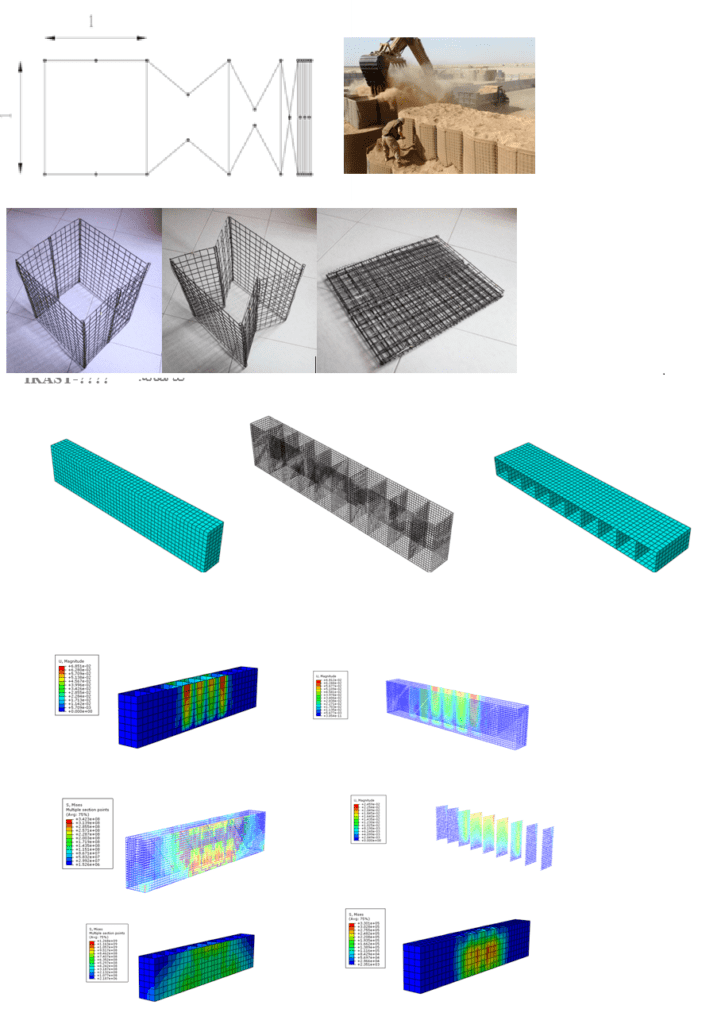

Modeling of durable reinforced blocks for use in fast and economical construction of reinforced walls

Unsubmitted

Soheil Esfandiari

The conditions for maintaining safety at its outermost level, enclosing that place with a wall or a safe device against destructive forces, is a priority. This place can be in small areas such as military trenches in order to maintain the safety of fewer people or at a higher level of importance such as temporary or permanent military bases and temporary or permanent military camps. The purpose of presenting this plan is to provide a solution to build a wall with sufficient strength while being easy to implement in a short period of time and with less manpower that can ensure people’s safety. In this research, it has been tried to help this wall by arming it in order to maintain its stability and prevent it from falling after the explosion. In cases of application of these prefabricated walls for external protection, such as camps and places of high importance, the wall must be designed in such a way that it can show sufficient stability against the pressures caused by explosions or the impact of heavy equipment against overturning and sliding. In order to achieve the goal of quick installation of the blocks, it is designed as a scissor-like opening, which has a good installation speed with a small transfer volume. The analysis results obtained with the help of simulation software and small-scale laboratory samples show the high efficiency of these blocks.

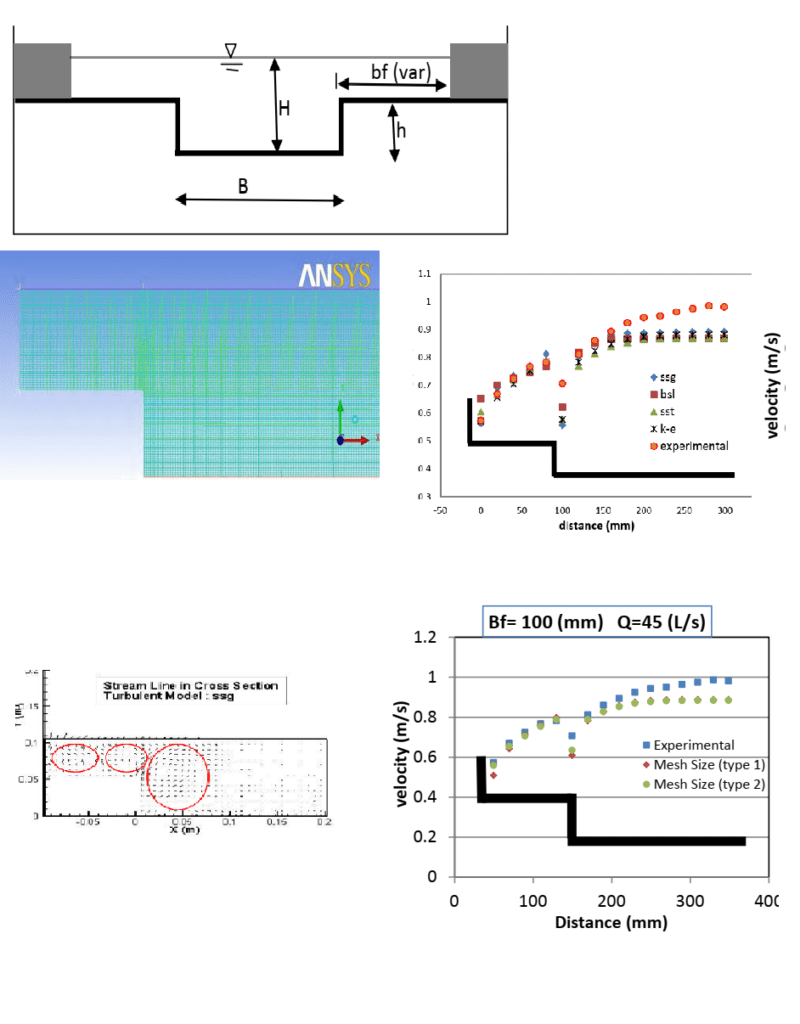

Comparison of different turbulent models for numerical simulation in compound channels

9th International Congress on Civil Engineering, Isfahan –Iran

Rezaei B, Esfandiari. S, Fazli M, (2012)

In this research, you have tried to use different models of turbulent flows in mixed channels with the help of numerical simulation. By comparing various simulation models for water flow and choosing the best one according to the available laboratory results, parametric analyzes on the channel and flow behavior and its speed change were obtained.